Thermoplastic Rubber Uses

2 thermoplastic polyolefins tpe o or tpo these materials are blends of polypropylene pp and un crosslinked epdm rubber in some cases a low degree of cross linking is present to boost heat resistanc and compression set proprties.

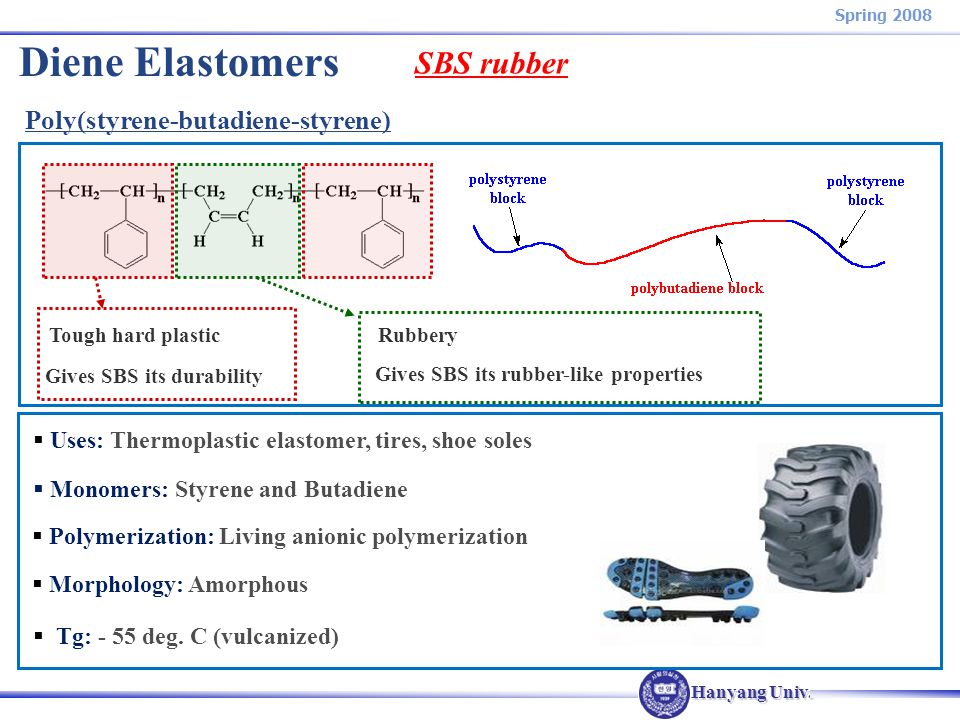

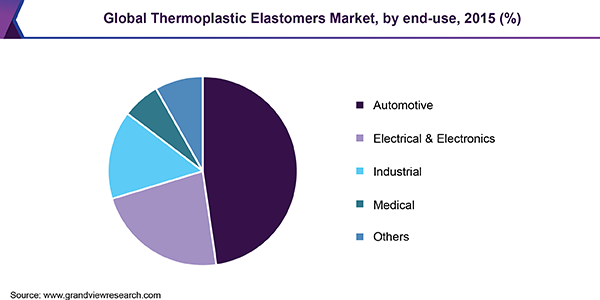

Thermoplastic rubber uses. Recent years have seen the rise of new thermoplastic materials. Thermoplastic elastomers tpe sometimes referred to as thermoplastic rubbers are a class of copolymers or a physical mix of polymers usually a plastic and a rubber that consist of materials with both thermoplastic and elastomeric properties. It is lightweight and has good abrasion resistance good tear strength weather resistance and electrical properties. Thermoplastics are a mix of synthetic rubber and plastics.

Thermoplastic elastomers tpe are versatile plastics that are perfect for sealing coextrusions and other solutions. Tpr performs similarly to vulcanized rubber and is reusable and recyclable. Although they can have a rubbery feel and are sometimes called thermoplastic rubber they are not made out of rubber. They are used in applications where there is a requirement for increased toughness over the conventional pp.

It has seen wide use in commercial and industrial applications. Thermoplastic elastomers are thermoplastics with an elastomeric component that makes them soft and flexible. About thermoplastic rubber tpr tpr material also known as thermoplastic rubber is a material that has properties of both plastic and rubber. We stock a thermoplastic material known as santoprene.

While most elastomers are thermosets thermoplastics are in contrast relatively easy to use in manufacturing for example by injection molding. A thermoplastic or thermosoftening plastic is a plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling. Tpes can be very rigid or very soft and gel like. The most popular methods of processing thermoplastics are injection molding extrusion and thermoforming the thermoplastics can be like rubber or as strong as aluminum depending on their chemistry they are light weight some thermoplastic materials can withstand the temperature extremes up to 600 f while the others retain their properties at 100 f.

Unlike thermoset rubber tpes do not require curing or vulcanization as they are true thermoplastics. Timco rubber designs and provides custom flexible and rigid tpe parts for companies in need of quality products for their applications. It was developed in 1977 by monsanto company and is now owned by exxon mobil. Most thermoplastics have a high molecular weight the polymer chains associate by intermolecular forces which weaken rapidly with increased temperature yielding a viscous liquid in this state thermoplastics may be reshaped.

.jpg)