Silicone Rubber Thermal Expansion

The coefficient of volumetric thermal expansion for all silicone rubber products is in the range of 5 9 to 7 9 x 10 4 4 c.

Silicone rubber thermal expansion. Silicone rubber withstands high and low temperatures far better. Silicone rubber for low temperature applications ke 136y general purpose silicone rubber ke 951 nitrile rubber chloroprene rubber chloroprene rubber deteriorates rapidly and discolors at temperatures between 150 250 c but there is little change in silicone rubber even at 250 c. Carbons 1 2 to 2 5 x 10 6 2 16 to 4 5 x 10. Thermal expansion is usually expressed in one of two ways either volumetric expansion or more commonly linear expansion expressed as a coefficient.

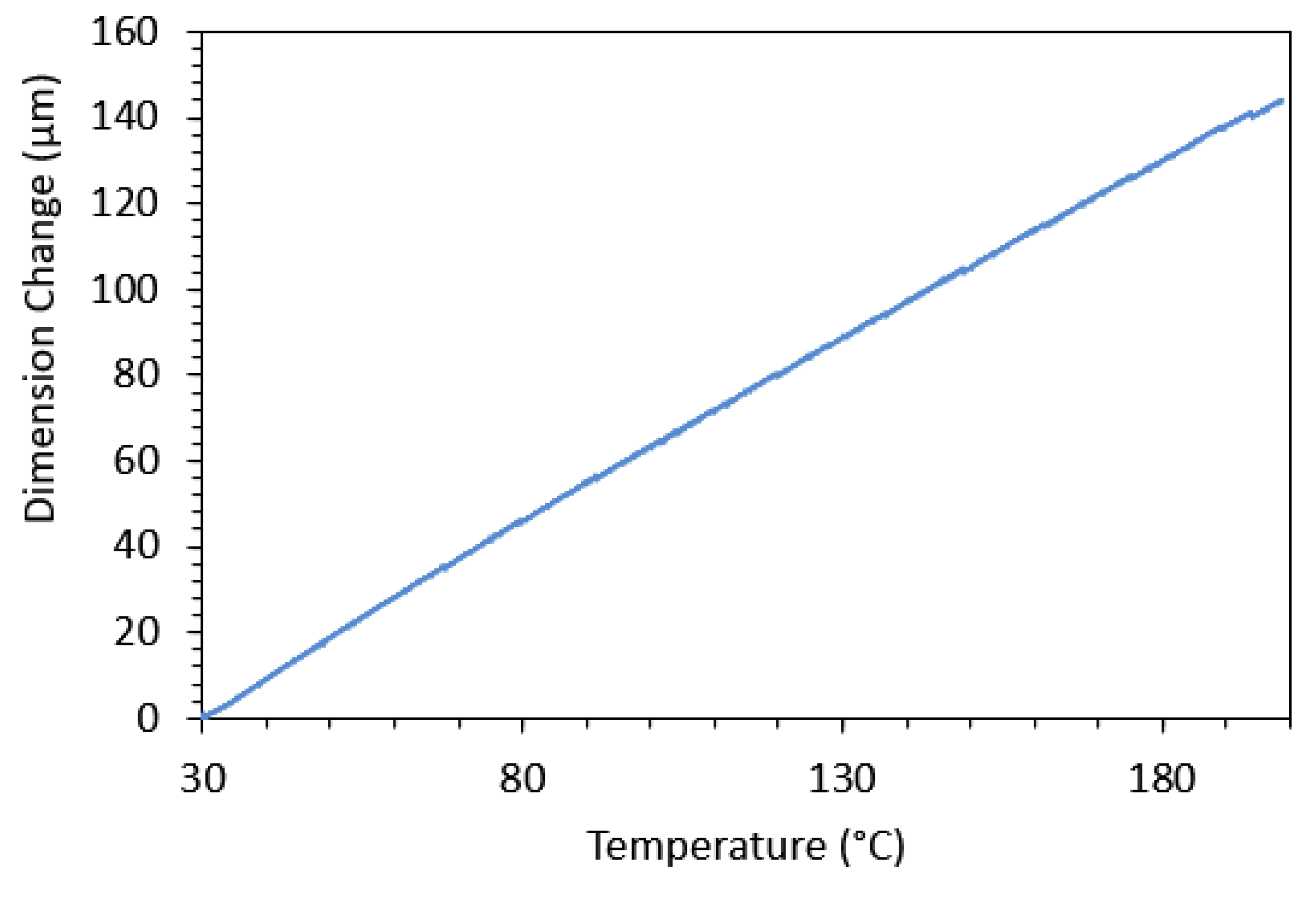

Key properties include thermal stability chemical stability electrical insulation and low toxicity. These forces are generated by thermal expansion of the rubber and or swelling effect of a fluid. Coefficient of thermal expansion silicone has a high thermal expansion coefficient and can be used as a temperature activation method or sensor in the design. This expansion is an advantage for sealing applications.

If the seal is completely confined and the gland is 100 filled the dominating force is the force of thermal expansion of the rubber. Rubber and silicone lsr thermal expansion. Silicone rubber is an elastomer rubber like material composed of silicone itself a polymer containing silicon together with carbon hydrogen and oxygen silicone rubbers are widely used in industry and there are multiple formulations. They vary according to polymers.

Calculate the length change of a bronze bar l 5m α 18 10 6 c if the temperature rises from 25 c to 75 c. Silicone rubbers are often one or two part polymers and may contain fillers to improve properties or reduce cost. There have been instances where a seal has ruptured a steel gland due to expansion when heated. Silicones are polymers with a si o si backbone.

Untreated silicone in gel or liquid form will convert to solid after curing. They expand under temperature increase influence their coefficients of linear expansion will directly be function of loads rates. There are different types depending on functional groups in the structure and curing mechanisms. Silicone rubber 190 0 x 10 6 342 0 x 10 6 mech.

The usual values are from 2 to 4 x 10e 4 unity ke 1. Main applications are flexible seals o rings etc. The coefficient of thermal expansion is defined as the change in length or volume of a material for a unit change in temperature. For example silicone may expand linearly 5 9e 4 to 7 9e 4 in in c compared to aluminum at 23 0e 6 in in c or steel at 10 8e 6 in in c.

The curing method can be either vulcanized or catalyzed. Thermal expansion can present significant challenges for designers in certain areas for example when constructing spacecraft aircraft buildings or bridges but it can have positive uses. Materials commonly named rubber are hot cured or high temperature vulcanisation elastomers hcr or htv.