Rubber Tensile Test Standard

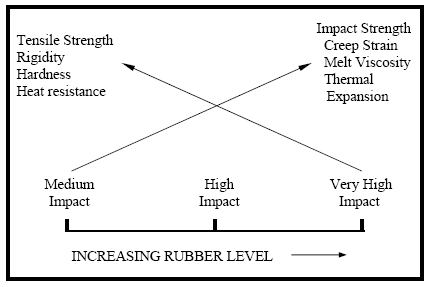

From these measurements the following properties can also be determined.

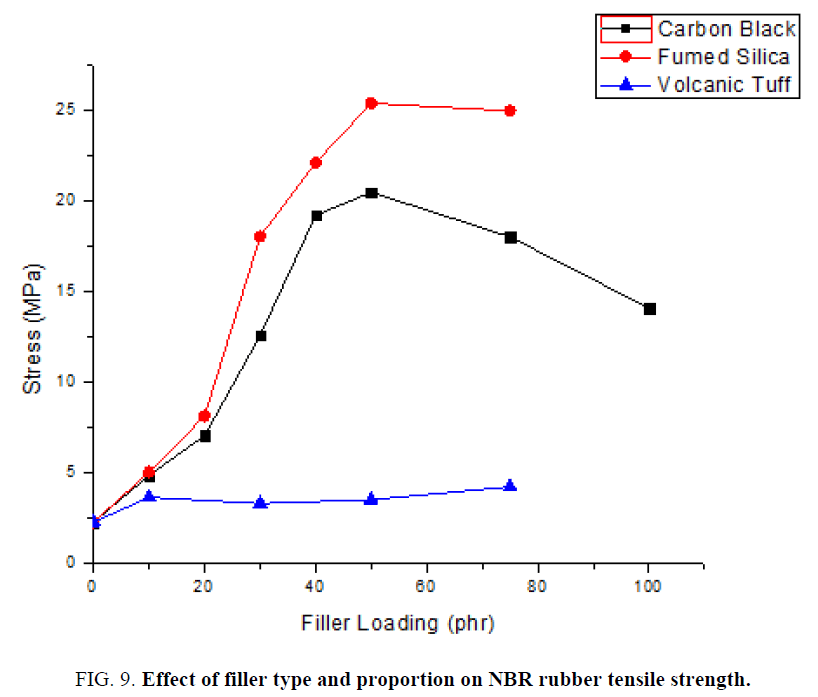

Rubber tensile test standard. D3577 09 2015 standard specification for rubber surgical gloves. British gaskets required a test system to ensure the rubber and polymer materials neoprene viton epdm and silicone meet their quality control standards and were fit for purpose. Astm s rubber standards are instrumental in specifying testing and assessing the physical mechanical and chemical properties of a wide variety of materials and products that are made of rubber and its elastomeric derivatives. Tensile stress yield point and tensile strength are based on the original cross sectional area of a uniform cross section of the specimen.

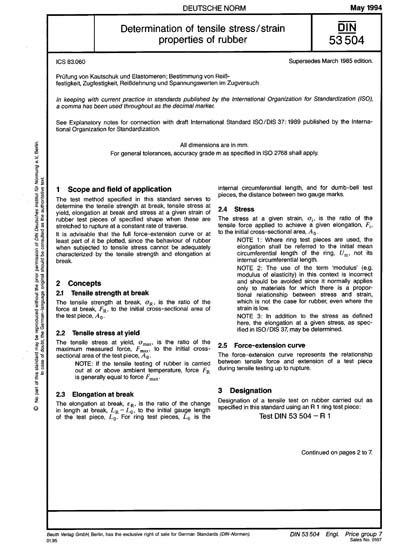

Tensile tests of rubber dumb bell specimens standard no. Standard test methods for rubber o rings. Iso 37 2017 specifies a method for the determination of the tensile stress strain properties of vulcanized and thermoplastic rubbers. Standard test method for tear strength of conventional vulcanized rubber and thermoplastic elastomers.

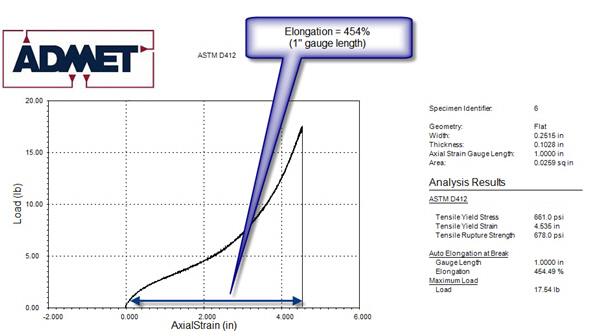

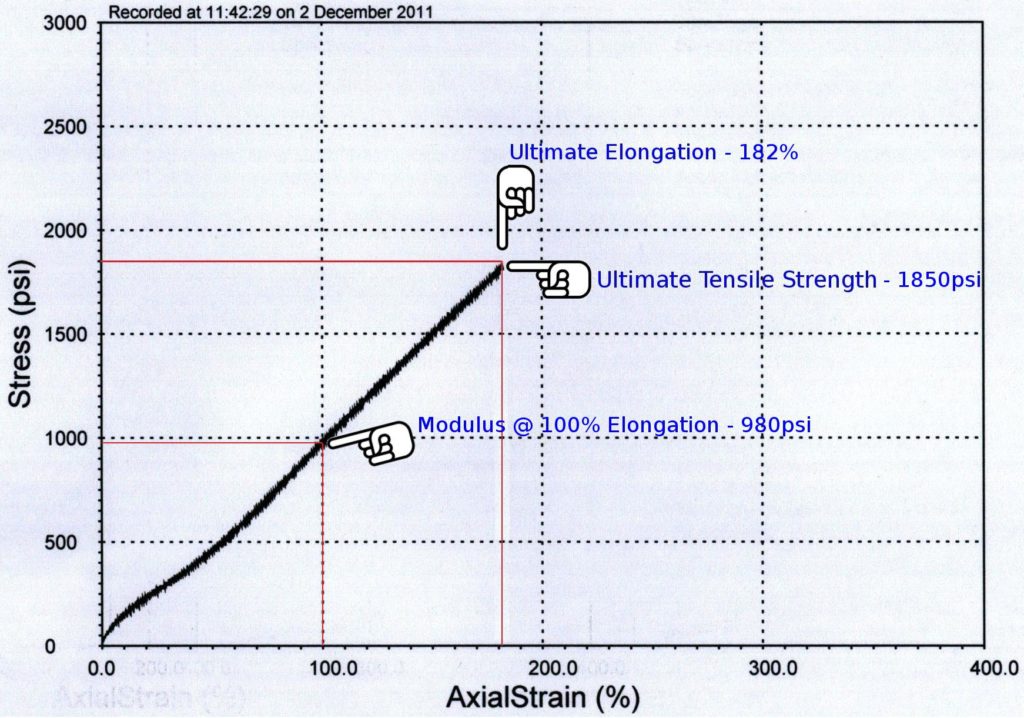

2010 introduction rubber materials have characteristic mechanical properties including elasticity and flexibility and are widely used for industrial parts construction materials and housewares. The properties which can be determined are tensile strength elongation at break stress at a given elongation elongation at a given stress stress at yield and elongation at yield. Requirement british gaskets are a major manufacturer of gaskets sealing products and mouldings. Properties that are directly measured via a tensile test are ultimate tensile strength breaking strength maximum elongation and reduction in area.

Tensile testing also known as tension testing is a fundamental materials science and engineering test in which a sample is subjected to a controlled tension until failure. Method a for astm d412 is a common test for dogbone and strip samples of rubber and elastomers. 5 1 all materials and products covered by these test methods must withstand tensile forces for adequate performance in certain applications. However tensile properties alone may not directly relate to the total end use performance of the product because of the wide range of potential performance requirements in actual use.

These are made from a variety of materials to suit a range of applications. D1456 86 2014 standard test method for rubber property elongation at specific stress. Preview whitepaper download multitest with els loadcell performing tensile testing on rubber dumbbell sample astm d412 common tensile testing standards some of the most common tensile testing standards we re asked about by our.