Rubber Press Sheet Metal Forming

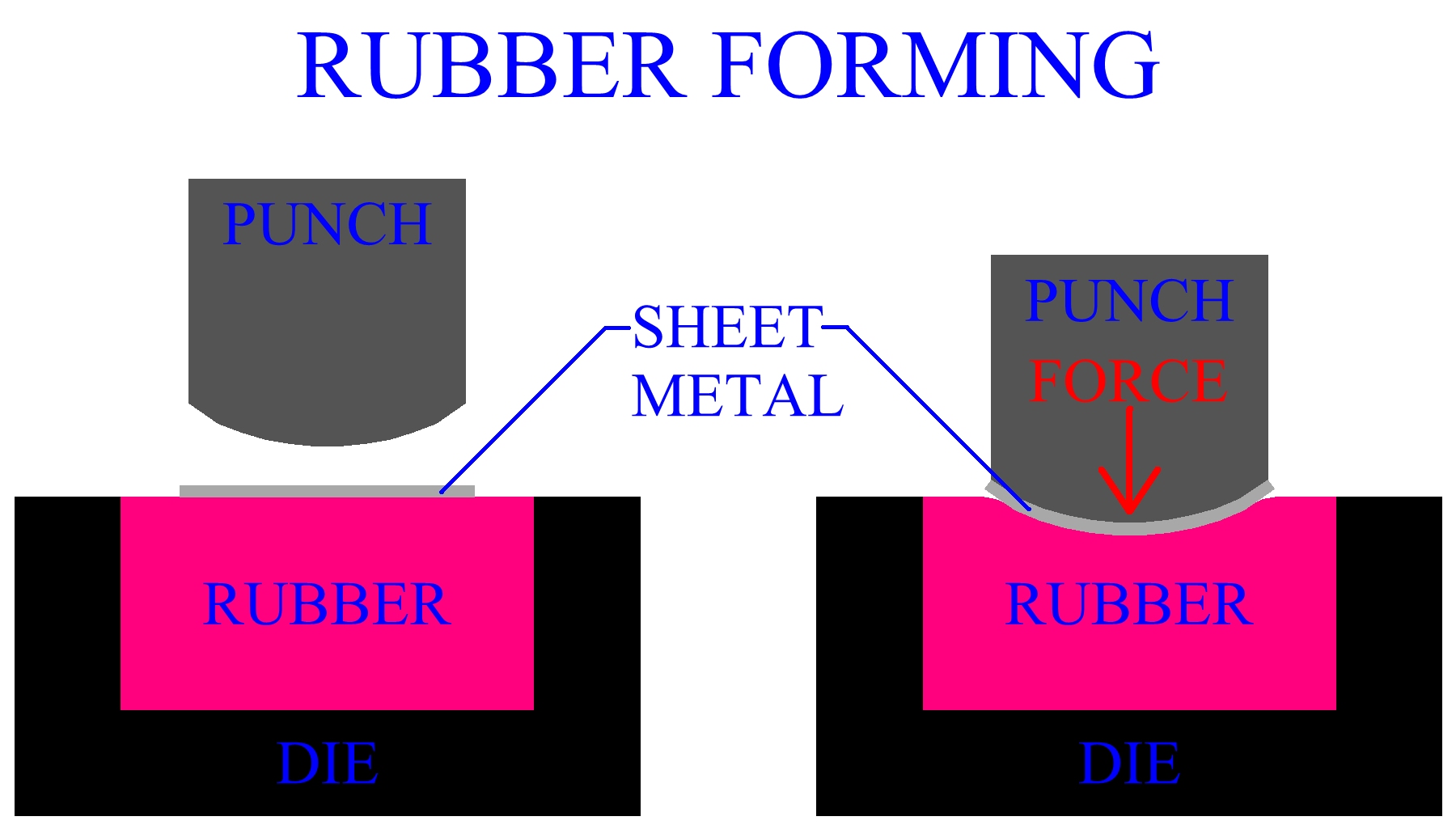

Often the rubber is incased in a steel container and serves as a punch.

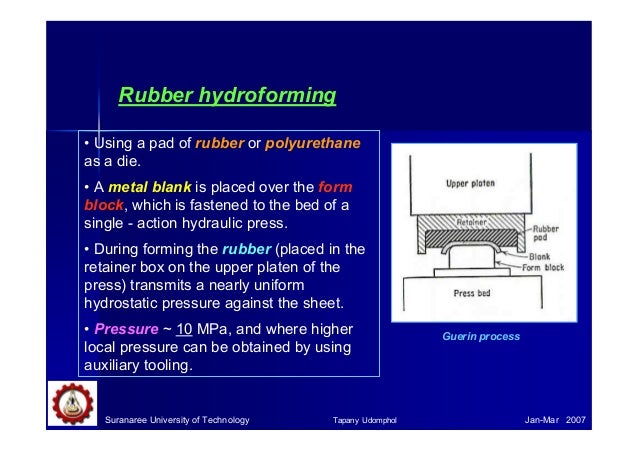

Rubber press sheet metal forming. These machines can also consolidate multiple steps into a single cycle virtually eliminating secondary finishing processes such as polishing. The blank of sheet metal work piece is placed on the die. Hydraulic press manufacturer exporter supplier from india. Similar to rubber pad forming sheet hydroforming offers all of the same benefits plus a more even distribution of force across the part s surface.

Solid rubber pad forming process. The forming block was machined on a cnc mill. The rubber pad forming sheet metal parts having without stress. The flat part was punched on a cnc punch press.

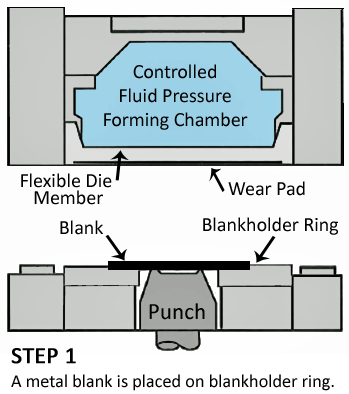

A work piece is placed over a rigid die. The inexpensive tooling and ability to run multiple parts in a single cycle are amplified in our line of triform sheet hydroforming presses. Sheet hydroforming presses can combine and or replace many different metal forming processes including press brakes traditional draw forming rubber pad forming progressive die forming and more. Rubber press forming a small rib for a horizontal stabilizer.

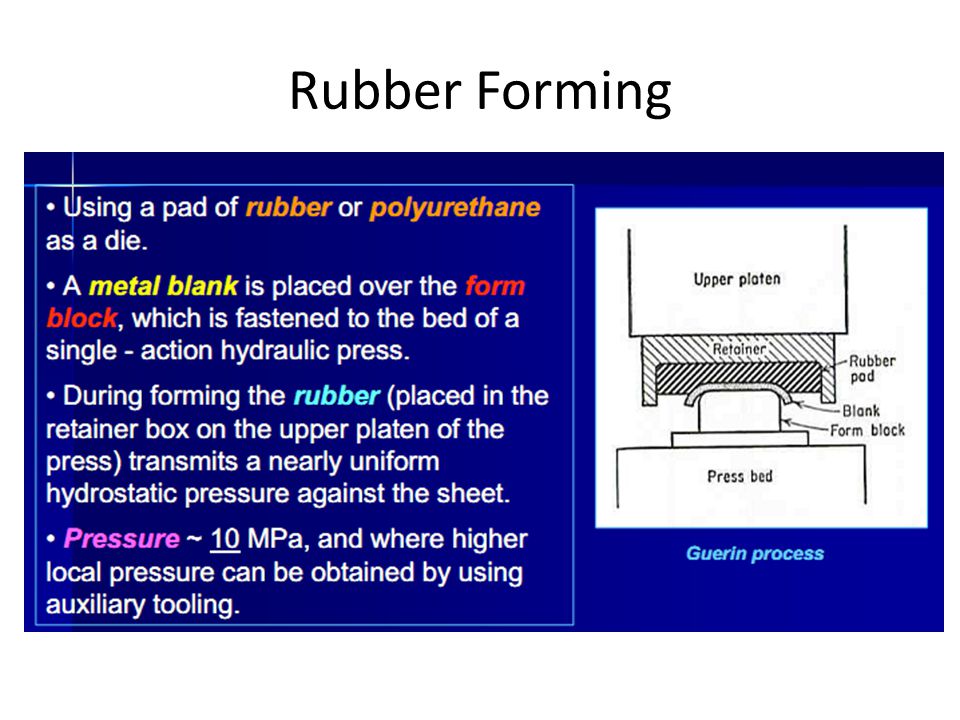

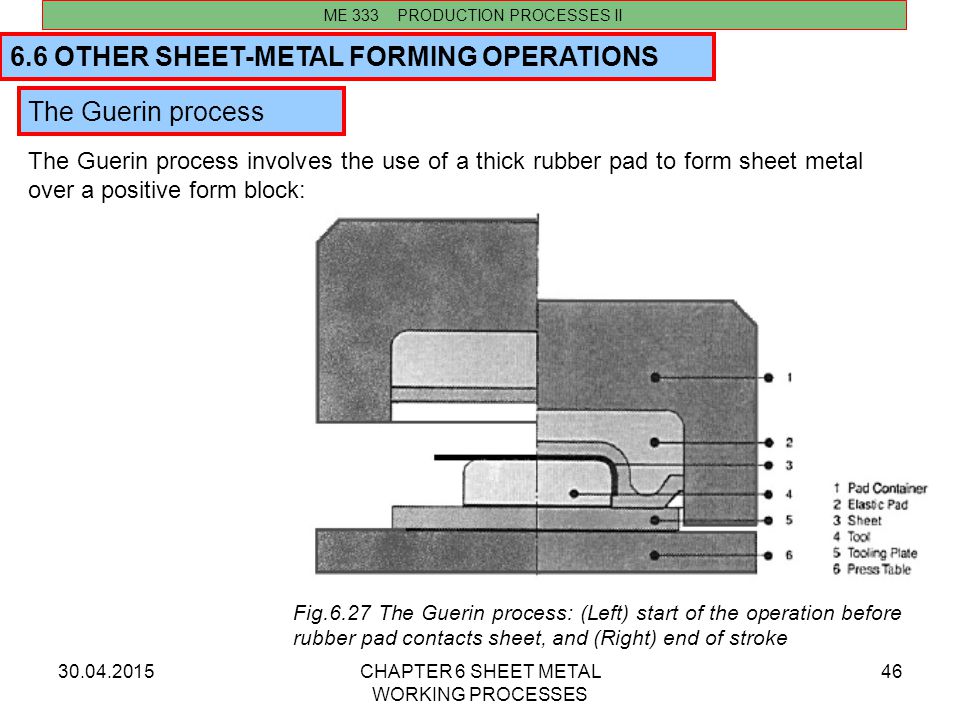

The rubber pads can have a general purpose shape like a membrane. It is easy and requires application of rigid container fillet with solid rubber pad. Rubber forming rubber forming uses a flexible material such as rubber or polyurethane to form a sheet metal work piece. The kicker with this build is that there is no fluid at least not until the 40 000 pound hydraulic press semi liquifies the thick neoprene rubber pad placed over the sheet metal blank and die.

Before the forming process the blanks are precut to their final dimension. The punch forces the work into the rubber. Thermoset urethane is an excellent option for forming pads used in hydraulic forming presses. Cold forging hydraulic press hydraulic presses in c frame closed frame four pillar four column pre stretched tie rod aluminium extrusion press copper brass extrusion press non ferrous metal extrusion press hydraulic deep drawing press sheet metal forming press rubber moulding press etc.

Alternatives to rubber pad forming and elastoforming. Rubber pad forming rpf is a metalworking process where sheet metal is pressed between a die and a rubber block made of polyurethane under pressure the rubber and sheet metal are driven into the die and conform to its shape forming the part. A beckwood 400 ton rubber pad forming press making 5 different parts in one cycle. Under pressure the forming pad molds the sheet metal into the shape of the die thus forming the part.