Rubber Curing Systems

Preparation and curing of rubber compounds.

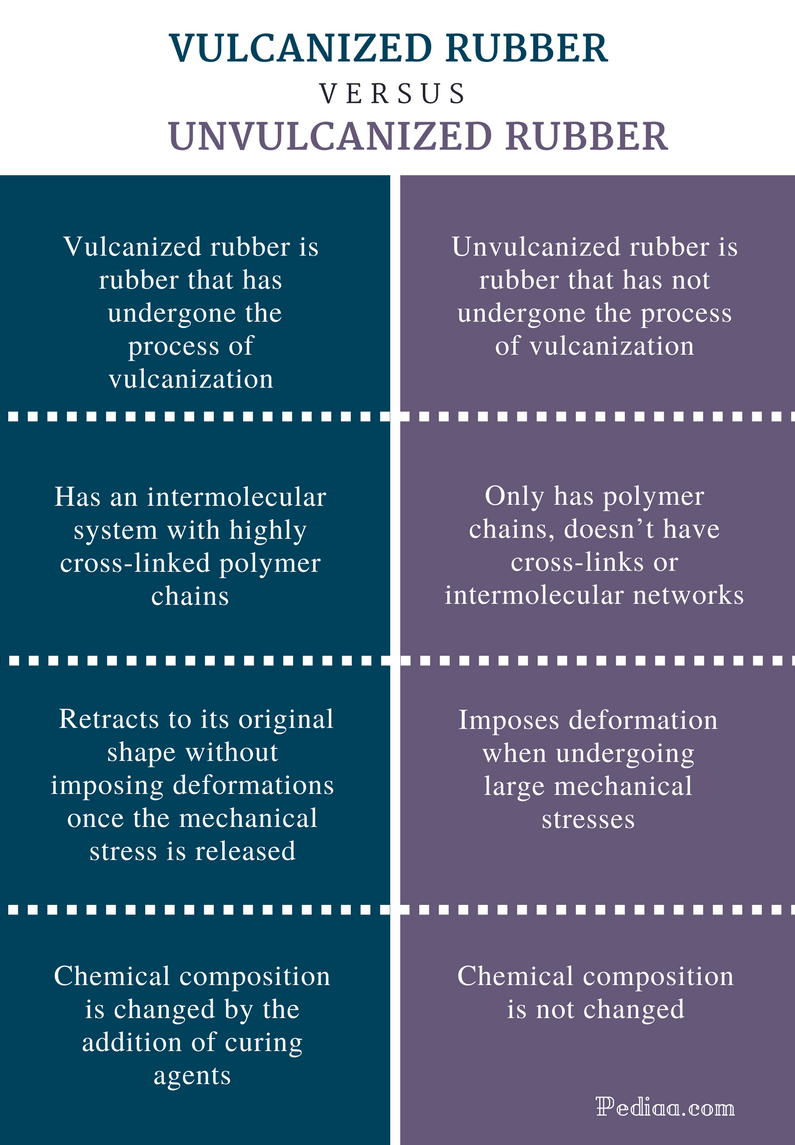

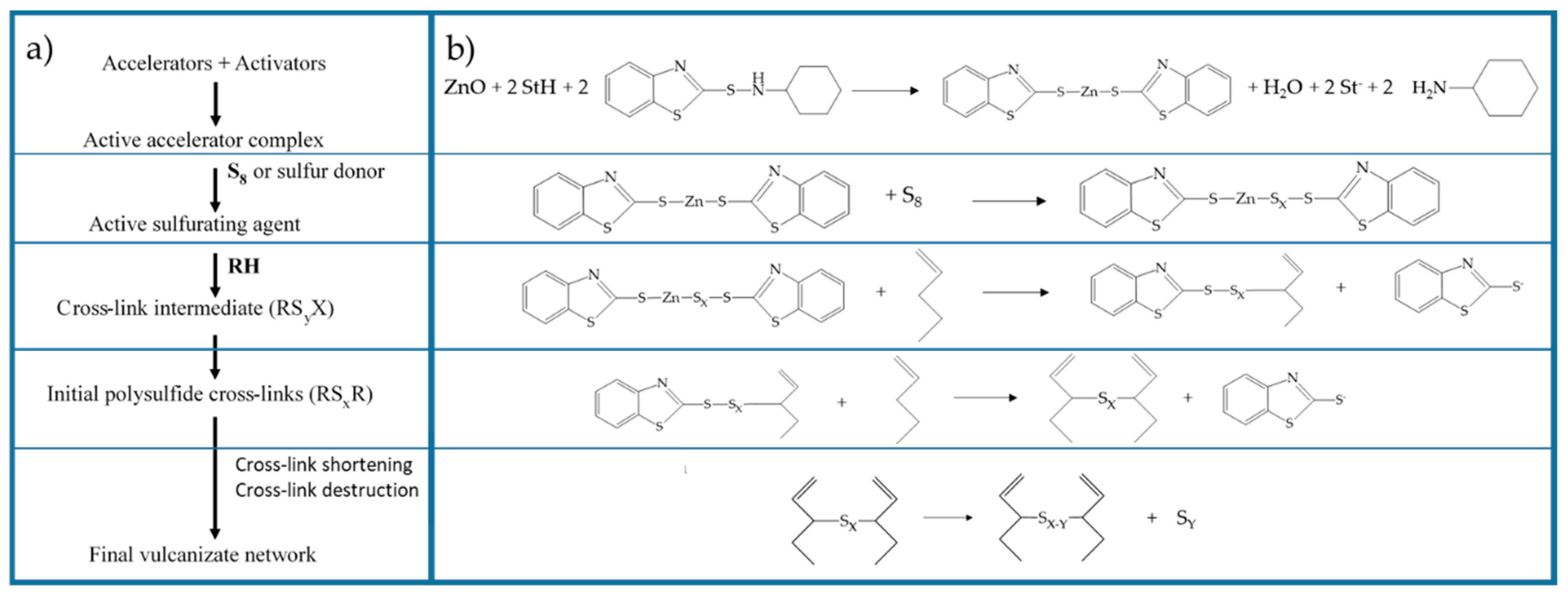

Rubber curing systems. The term originally referred exclusively to the treatment of natural rubber with sulfur which remains the most common practice. Even if it is strongly associated with the production of thermosetting polymers the term curing can be used for all the processes where starting from a liquid solution a solid product is obtained. Charles goodyear has been credited for the earliest method of crosslinking. In this section summary of our experimental studies are described.

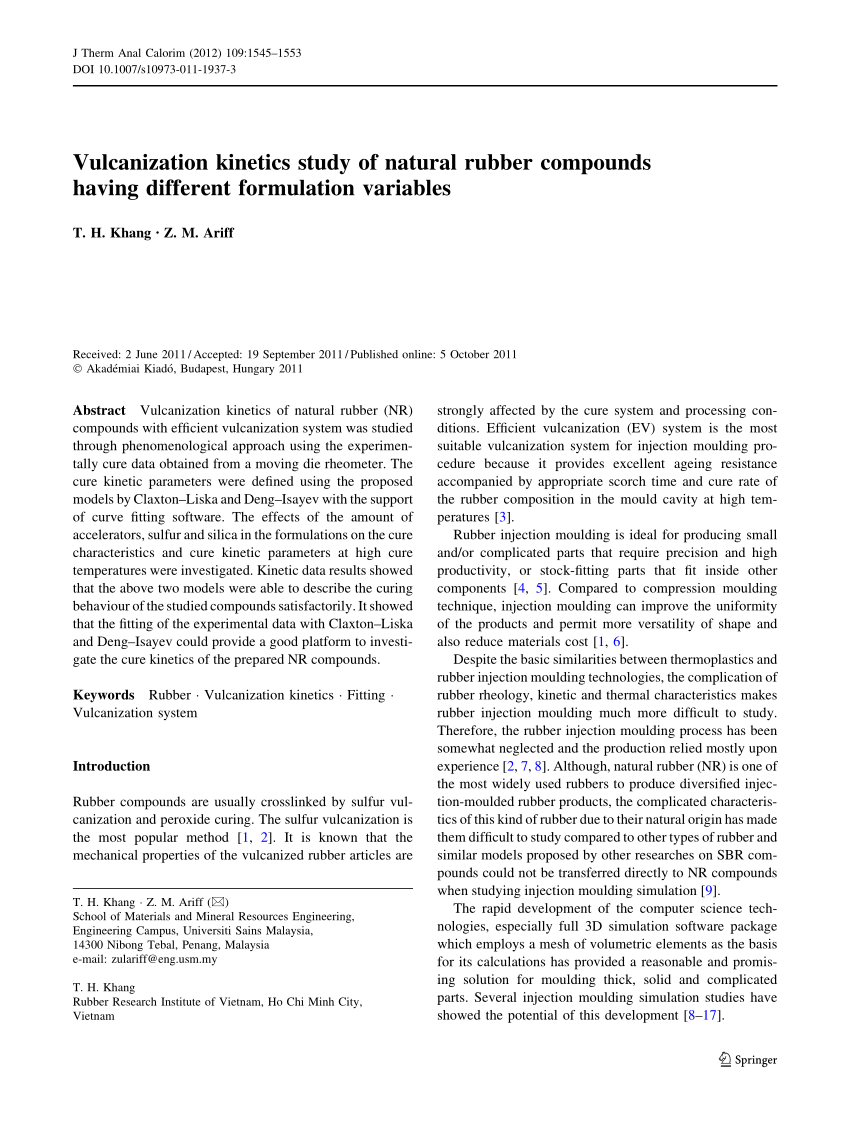

However it has also grown to include the hardening of other synthetic rubbers via various means examples include silicone rubber via room temperature vulcanizing and. His process heating rubber with sulfur was first successfully used in springfield massachusetts in 1841. Vulcanisation refers to a range of processes for hardening rubbers. Experimental methods the most typical curing agent is sulfur and another type of the agent is peroxide e g.

Rubber curing systems 1 introduction crosslinking or curing i e forming covalent hydrogen or other bonds between polymer molecules is a technique used very widely to alter polymer properties. The process of crosslinking is called curing or vulcanization and the chemicals used for curing are referred to as curing agents or cure systems. Is an equipment manufacturer of rubber machinery for vulcanizing curing microwaves flocking cooling and material handling. A prediction method for rubber curing process 153 2.

One is the styrene butadiene rubber with. The compounding of additives was carried out in a laboratory kneading machine brabender. First the rubber was plasticated for 2 min at 80 c and 55 rpm then the components of curing system were added and rubber compounds were compounded for next for 4 min at 80 c and 55 rpm. The uses of primary and secondary accelerators prevulcanisation inhibitors pvis and antireversion chemicals are outlined typical rubber formulations for applications in industrial rubber products and tyres are given.

Along with this we have expanded to other equipment manufacturing outside of the rubber industry such as non rubber related ovens burner systems automated conveyor lines and more. This review discusses the different types of curing systems available today for different rubber types including natural rubber sbr nbr br iir cr xiir and epdm. Two types of curing systems were examined. The first commercial method of crosslinking has been attributed to charles goodyear.

Crosslinking or curing i e forming covalent hydrogen or other bonds between polymer molecules is a technique used very widely to alter polymer properties.